Pressure Blaster - SB10

12366

The pressure pot for sandblasting systems is a powerful and efficient solution for sandblasting glass objects and other hard materials.

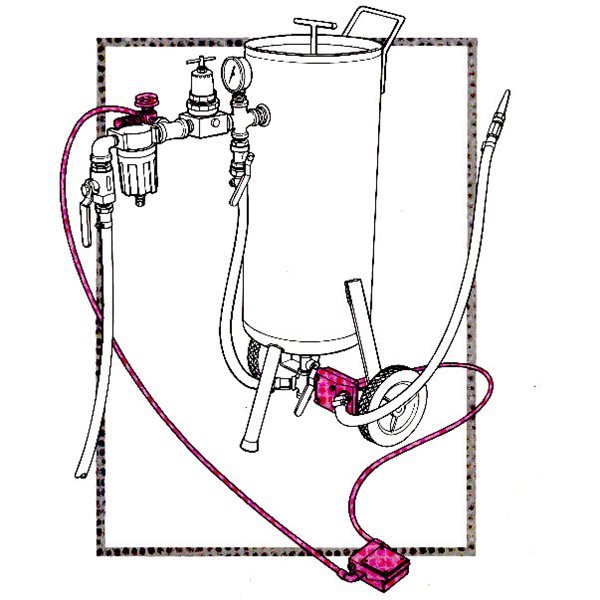

The pressure pot for sandblasting systems is a powerful and efficient solution for sandblasting glass objects and other hard materials. Equipped with a variety of useful features, the pressure pot offers precise and convenient operation with significant time and efficiency benefits.

Scope of delivery:

- Foot switch assembly incl. hoses – for easy operation during sandblasting.

- Pressure regulator for foot pedal set – for precise adjustment of the pressure at the foot switch

- Sand/air hose to the cabin – for connection from the pressure pot to the sandblasting cabin.

- Water separator – to avoid moisture in the sand/air flow.

- Regulator valve for sand-air mixture – for precise mixing and control of the blasting effect.

- Manometer for tank pressure adjustment – for precise adjustment of the blasting pressure.

- Choke valve – to release possible blockages in the sand/air path

Technical data:

- Capacity: 44 litres

- Dimensions: approx. 830 x 330 x 480 mm (H x W x D)

- Weight: 22 kg

- Mobility: 2 sturdy rollers for easy movement and positioning of the pot.

Advantages of the pressure pot:

- High efficiency: The pressure pot is about 8 times faster than conventional siphon systems, which significantly reduces working time.

- Precision for detailed work: Particularly suitable for detailed blasting processes and fine surface treatments.

- Versatility: Ideal for relief blasting, perforation and processing edges in different variations.

- Cost-effective: the pressure vessel requires less compressed air, which reduces the load on the compressor and lowers energy consumption.

- Recyclable: the blasting material can be easily reused via a funnel with a filter.

- Durable and low-maintenance: the pressure pot is extremely robust, has few wear parts and requires little maintenance.

Functionality: The pressure potl is an alternative to conventional sandblasting with a gun with a siphon system. With the siphon system, the sand is sucked in, whereas with the pressure pot, the sand is under pressure in the pot and is ejected by activating the foot switch. This leads to a significantly reduced working time.

Optimisation of glass sandblasting:

- Fine precision: The pressure pot is particularly suitable for sandblasting glass, where a wide range of surface treatments are possible. The infinitely variable pressure adjustment allows various effects to be achieved.

- Soft frosting (approx. 10 psi / 0.7 bar): Creates a very fine, silky matt surface with infinitely variable transitions.

- Homogeneous, cloud-free surfaces (approx. 20-25 psi / 1.4-1.7 bar): The surface is textured, but remains smooth and translucent in the light.

- Deep etching or "carving" (approx. 30 - 40 psi / 2.1 - 2.8 bar): Ideal for deeper etching processes, e.g. for 'drilling' openings or for organically shaped edges.

Easy maintenance: The pressure pot requires only minimal maintenance and has few wear parts, which ensures its durability and reliability.

12366 38.000000